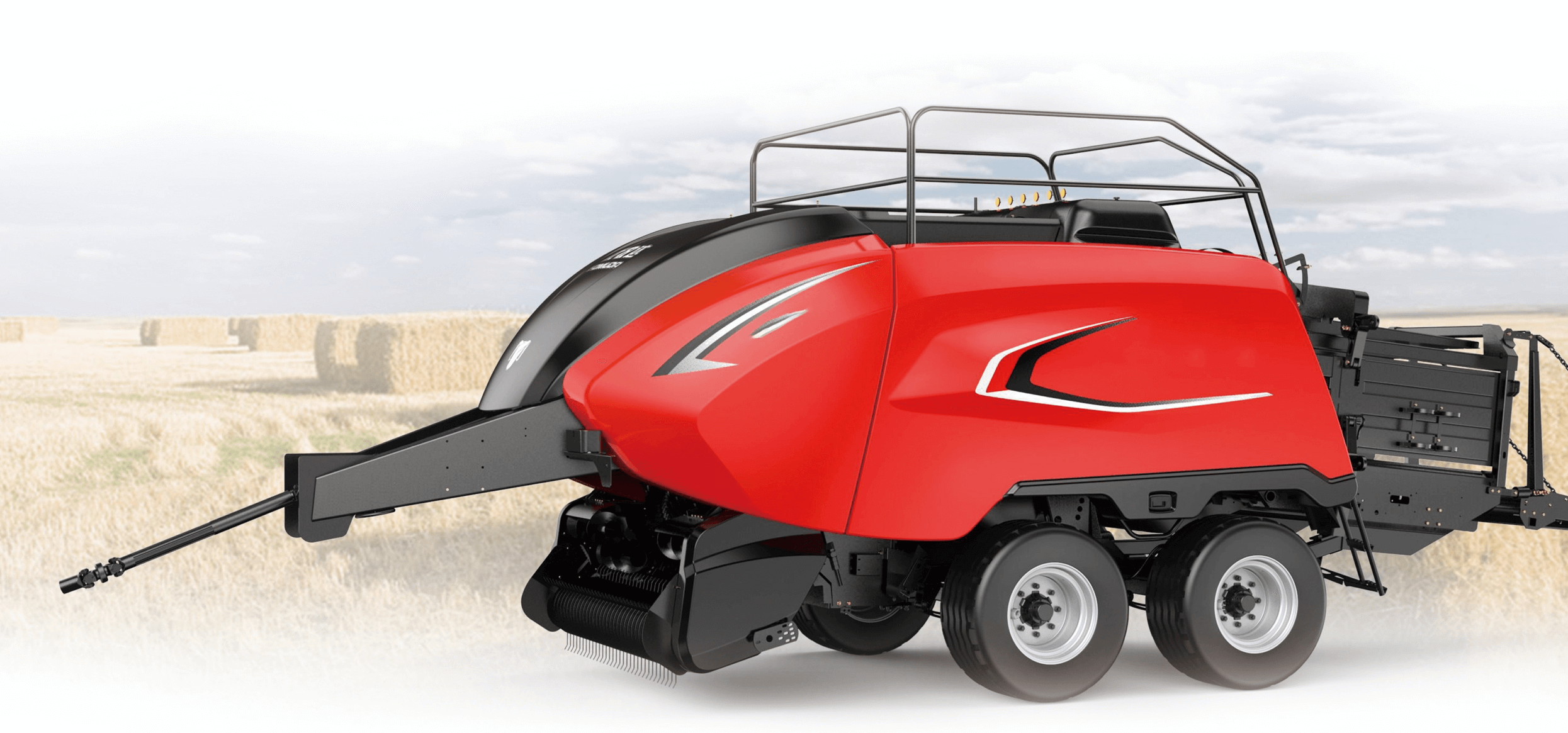

Large Square Baler

- Bale length(mm): Max.2743

- Number of Tines/ Tine Spacing(mm): 128/66

- Baling plunger speed(Strokes/ minute): 47

- Cross section(mm): 1200*900

The Large Square Baler

This large square baler features a double-linked shaft and imported wheel assembly, allowing for flexible operation using the tractor's hydraulic remote control lever. The reliable Rasspe knotter utilizes imported maintenance-free bearings, and key structural components are made from high-strength, wear-resistant materials. The robust piston structure effectively compresses grass into the baling chamber and includes three pairs of adjustable, maintenance-free piston rollers, enhancing safety. The pickup assembly is equipped with two augers that efficiently convey crops to the feeder, preventing overload and collisions, ensuring the machine operates reliably over time.

The Advantage of Large Square Baler

-

The knotter of this machine adopts an imported Rasspe knotter,which is reliable, sturdy, and durable.

-

The main parts of the entire frame are made of high strength and wear-resistant plates, using high strength welding materials, making the frame more solid and durable.

-

All bearings used in the pickup are imported maintenance-free bearings.

- Total width/Effective pickup width(mm): 2998/2260

-

The axle of the towed square baler features a double-linked shaft and wheels with imported assembly, utilizing the tractor's hydraulic remote control lever to lock or an angle lock double-linked shaft, allowing for a tractor-trailer following steering axle.

The axle of the towed square baler features a double-linked shaft and wheels with imported assembly, utilizing the tractor's hydraulic remote control lever to lock or an angle lock double-linked shaft, allowing for a tractor-trailer following steering axle. -

- 1.The knotter of this machine adopts an imported Rasspe knotter,which is reliable, sturdy, and durable.

- 2.All the bearings on the knotter are imported maintenance free bearings.

- 3.The materials used for important structural components of the knotter are made from high-strength and wear-resistant plates.

-

The piston is a device that pushes the grass from the storage chamber into the baling chamber and compresses it. The overall structure is made of high-strength steel, which is more durable under the premise of meeting the usage requirements. It uses 3 pairs of maintenance-free piston rollers, the first 2 pairs are adjustable structures, which extend the life under frequent working conditions and also greatly improve the overall safety factor of the machine.

The piston is a device that pushes the grass from the storage chamber into the baling chamber and compresses it. The overall structure is made of high-strength steel, which is more durable under the premise of meeting the usage requirements. It uses 3 pairs of maintenance-free piston rollers, the first 2 pairs are adjustable structures, which extend the life under frequent working conditions and also greatly improve the overall safety factor of the machine. -

The main parts of the entire frame are made of high strength and wear-resistant plates, using high strength welding materials, making the frame more solid and durable.

The main parts of the entire frame are made of high strength and wear-resistant plates, using high strength welding materials, making the frame more solid and durable. -

- 1.This pickup assembly is equipped with two augers, which can move the crops towards the center of the pickup and into the feeder, resulting in good feeding efficiency.

- 2.This pickup is driven by the feeder, through the drive sprocket and two centering augers, with a one-way clutch between them and the feeder. When the spring teeth dig into the ground or the machine is not picking up crops quickly enough, the pickup clutch slips. The pickup clutch can prevent overload of the pickup or collision with field debris.

- 3.All bearings used in the pickup are imported maintenance-free bearings.

- 4.Important structural components are made of high-strength plates.

-

- 1.Stretchable bottom chamber, which can effectively and quickly clean out the bottom chamber and replace the bottom blade; optional bottom blades with adjustable cutting lengths are available.

- 2.Important structural components are made of high-strength plates, with stricter welding processes.

- 3.The feeding mechanism has two clutches, namely the pickup clutch and the feeding clutch, for more effective and faster feeding;

- 4.All bearings used are imported maintenance-free bearings.

Large Square Baler Common Specifications and Parameters

| Model | DFSB-1290 |

|---|---|

| Cross Section(mm) | 1200*900 |

| Bale Length(mm) | Max. 2743 |

| Overall Width(mm) | 3210 |

| Overall Length-with Bale Chute Raised (mm) | 8729 |

| Weight -Tandem Axlewith Cutter(kg) | 11600 |

| Total Width/Effective PickupWidth(mm) | 2998/2260 |

| Number of Tines /Tine Spacing(mm) | 128/66 |

| Protection Devices | Overrunning Clutch and Slip Clutch |

| Pickup Lifting | Hydraulic Cylinder Control |

| Grass-Pulling Fingers /Protection Devia | 6 grass-pulling fingers with surface heat treatment key-type slip cutch |

| Feeding Forks /Protection Device | Fork-type feeding forks /Shear bolts |

| Number of Knives (Optional)(Unit) | 0-13-26 |

| Number of Knotters /Twine Capacity | 6 double-knot knotters /30 balls |

| Twine Quality | High-quality plastic twine |

| Baling Plunger Speed(Strokes/Minute) | 47 |

| Baling Plunger Stroke(mm) | 740 |

| Tandem Axle | 620/40R-22.5 |

| Pickup Gauge Wheels | 4.8*8.0, 8-ply |

| Gearbox/Protection Device | Enclosed two-stage reduction,overrunning clutch,slip dutch,and shear bolt |

| Lights | Working lights,warning lights,turn signals |

| Display and Control Terminal | C1000 color screen |

| Bale Density Control | Hydraulic Control |

| Recommended PTO Power with Knives(HP) | 250 |

| PTO()Revolutions /Minute | 1000 rpm,21-spline |

| Hydraulic System | Two sets of double-acting hydraulic output valves |

For any enquiries, please fill in contact form.

Thank you for your cooperation.