Automatic Feeding Chaff Cutter Introduction

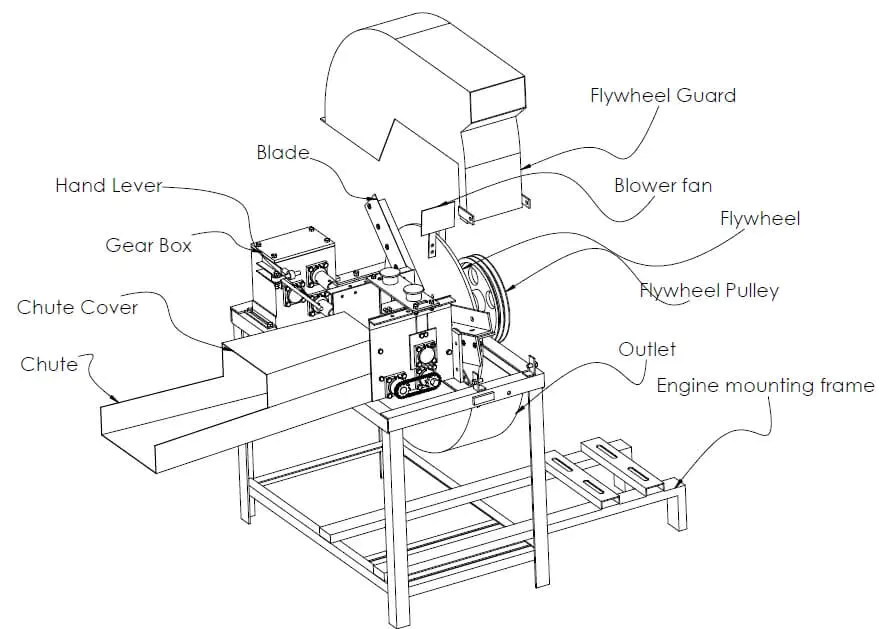

It is a kind of tractor operated chaff cutter equipped with gearbox and automatic feeding device.

The power-operated chaff cutter adopts an advanced feeding system that could feed raw material automatically, saving labors. It has the advantage of high capacity, fast feeding, and large capacity. Its production capacity varies from 4.5 tons per hour to 10 tons, which makes it the most favored chaff machine in large farms, dairy farms, and forage plants.

You may want to learn more about Manual Feeding Chaff Cutter?

Features of Tractor Operated Chaff Cutter

- Wide application. This machine can be used in the papermaking industry, fodder processing, organic fertilizer and environmental energy processing, animal husbandry, and other industries.

- It is the largest and most efficient chaff cutter in the whole market. The capacity range is 3-10T/h. Customers can choose different machines.

- Three-blade cutter set steel reinforced ring, rigid, strong, seamless; between the cutter and the spindle between the two-way adjustment nuts, easy to achieve axial movement, blade clearance adjustment more freedom.

- Advanced feeding mechanism, the unique feed roller device (has been national patent), automatic feeding, conveyor chain is not wrapped around the grass, feeding smooth, high production efficiency.

- Special gearbox for governor, which is easy to adjust the processed length.

- Equipped with rubber tire, it solves the moving problem of large equipment.

- There are multiple power choices such as motors, diesel engines, and tractors, so corn silage machine is especially suitable for regions in lack of power.

Application of Agriculture Straw Crushing Machine

The electric chaff cutter machine adopts a multiple-cutter device, which can cut all kinds of straws into very small pieces, such as the cotton straw, green/dry corn stalks, green branch, sorghum stalk, wheat straw, rape stalk, etc.

Installation of Electric Chaff Cutter

- ◆ Open the packing box and read the instruction manual before operation. First, install the bracket and motor, the chaff cutter wheel and motor wheel must be on the same plane. Then regulate the tightness of the belt, not too loose or too tight.

◆ After installing the feed hopper, check whether each part is loose or not. Install the cover firstly. Tighten the gland bolt and rotate the pulley by hand. See whether the rotating part is flexible, which ensures that pulley has no friction or collision. Finally check the motor rotation.

◆ When the whole installation is completed, users can make a motoring test firstly, ensures the chaff cutter is installed correctly.

◆ The rotating blade and bed-plate knife have been adjusted before delivery. Regularly check the tightness of each fastening bolt,especially the rotating blade and bed-plate knife.

◆ The rotating blade and base blade can be adjusted up and down. And the best distance between the two blades is generally 0.3 mm.

◆ When changing the fastening bolts of the fixed blade and rotating blade, must use the high strength bolt, instead of the regular fastening parts.

Technical Data of Tractor Operated Silage Chaff Cutter

|

Model

|

9ZP-3

|

9ZP-4.5

|

9ZP-6.5

|

9ZP-10

|

|---|---|---|---|---|

|

Power (KW)

|

4

|

5.5-15

|

5.5-15

|

5.5-15

|

|

Capacity (t/h)

|

≥3

|

≥4.5

|

≥6.5

|

≥10

|

|

Voltage (V)

|

380

|

380

|

380

|

380

|

Notices:

The production capacity of each model has a close relationship with the feeding materials, taking 9ZP-10 for example.

The performance indicators for 9ZP-10 Chaff Cutter for goat:

|

Items

|

Data

|

|

|

Productivity

(cutting length 16mm, continuous

and average feeding conditions )

|

green corn straw(78% moisture content)

|

10t/h

|

|

dry corn straw(78% moisture content)

|

3.5t/h

|

|

|

dry straw(78% moisture content)

|

4t/h

|

|

|

dry wheat straw(78% moisture content)

|

3t/h

|

|

|

dry alfalfa(20% moisture content)

|

3.5t/h

|

|

|

Cutting Length

|

3 moving blades

|

12, 18, 25, 35mm

|

|

Material Blowing Distance

|

10-15m

|

|

For any enquiries, please fill in contact form.

Thank you for your cooperation.