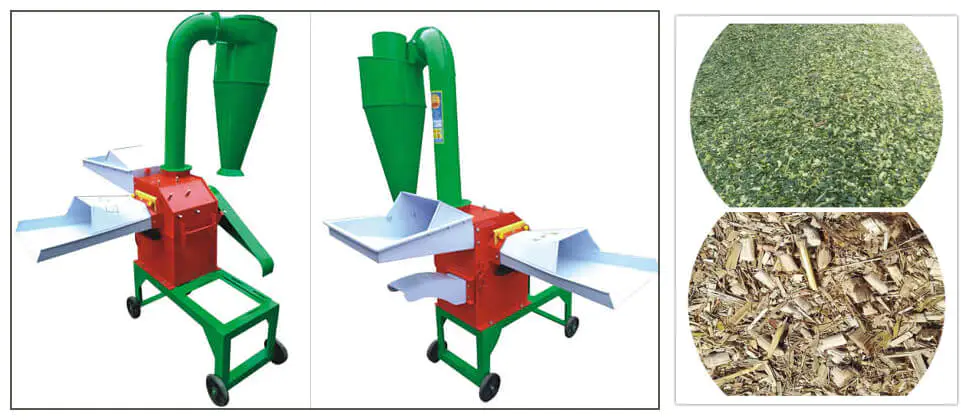

9ZF-400-30B Hay/Paddy Straw Chaff Cutter Machine Introduction

It is the only machine equipped with a cyclone dust-cleaning system among 9ZF series chaff cutters. It has three main functions- chaff cutting, grain milling, and dust collecting. The machine is equipped with a dust removal device, which avoids dust pollution and greatly reduces the harm to the human body. This machine not only can process grasses and straws into coarse fodder, but crush some granule grains into fine fodder, such as the corn, sorghum, wheat, and beans, etc. This machine is the most effective and economical equipment for small and medium-sized farms, livestock, and sideline processing farms.

9ZF-400-30B Hay Cutter Advantages

- No dust pollution,Low noise. This chaff cutter and grain grinder are equipped with cyclone dust collectors, which reduces human health.

- Wide application, strong practicability. This machine not only can cut various grasses and straws but crush many granular crops.

- The processed materials are much softer, which is helpful for livestock to absorb the forage.

- It is a mufti-function combined chaff cutter machine. It has the advantage of good performance, cost-effective, and high quality.

- Low energy consumption, high efficiency, smooth running, and durable.

Working Principle of 9ZF-400-30B Commercial Chaff Cutter

At the end of the housing, a rolling bearing is used as the main shaft. This machine is rotating at a high speed, which is driven by the motor to drive the main shaft and the turbine fastened at the main shaft. The machine is driven by the motor to drive the main shaft and the turbine on the main shaft. The turbine and grinding block constitute a reasonable and compact structure. So these raw materials are strongly rubbed and crushed during the rotation and crushed again in the gap between the blade and grinding block. Finally, the material is crushed to 1-50mm by adjusting the mesh. In brief, the material is fed by the feeding chopper and gradually crushed with the action of mesh and high-speed rotating hammer. Under the effect of centrifugal force, the materials are leaked out from the sieve holes and carried by the fan into the cyclone dust collector. In the end, the finished materials are out from the outlet of the cyclone dust collector.

Advantages of Cyclone Dust Collector System in Chaff Cutting Process

Dust collectors play a major role in helping poultry farmers meet these requirements and improve both indoor and outdoor environments by capturing a high percentage of the particles emitted by the hay/paddy straw cutting process. Cyclone collectors are gaining in popularity. A cyclone dust collector can be an essential health-related part of the chaff cutting shop setup-especially if you have large amounts of chaff cutting work there.

Before introducing the dust-collecting hay/paddy straw cutter machine, let’s have a brief introduction of 9ZF series commercial chaff cutter. In the previous articles, we have detailed that 9ZF series chaff cutter has two functions: silage fodder cutting and grain milling. Therefore, we call it: Chaff Cutter cum Grain Grinder. The model number of the duct-free chaff cutter is 9ZF-400-30B, which means that it also has multi-functions, both cutting and grinding. Its full name is commercial chaff cutter cum grain grinder machine with cyclone dust collector design.

Technical Data of 9ZF-400-30B Chaff Cutter Machine

|

Model No.

|

9ZP-400-30B

|

|

Main shaft speed

|

3000r/min

|

|

Matched Power

|

2.2-3kw

|

|

Rotor diameter

|

360mm

|

|

Motor Speed

|

2800r/min

|

|

Rated Voltage

|

220V

|

For any enquiries, please fill in contact form.

Thank you for your cooperation.