Introduction to Pig Farrowing Crate

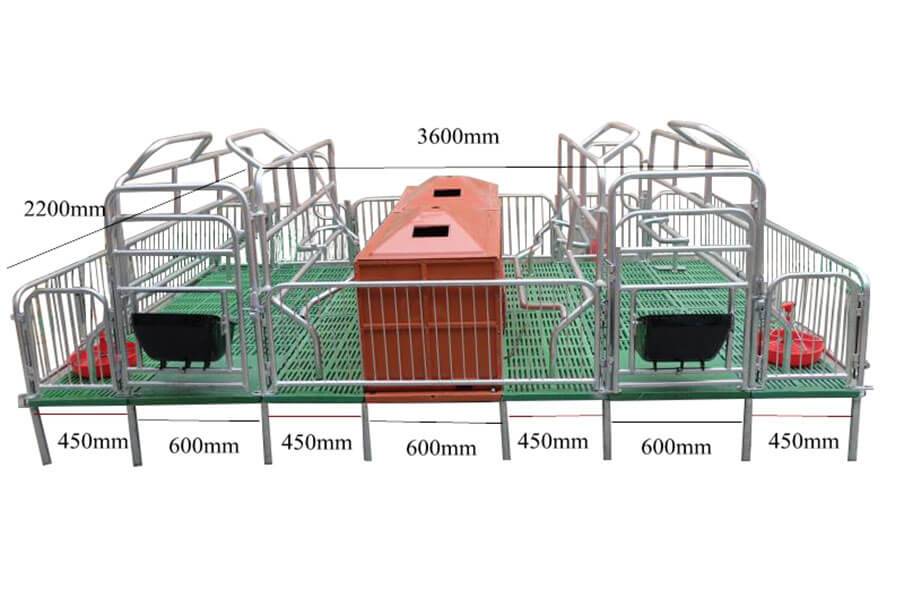

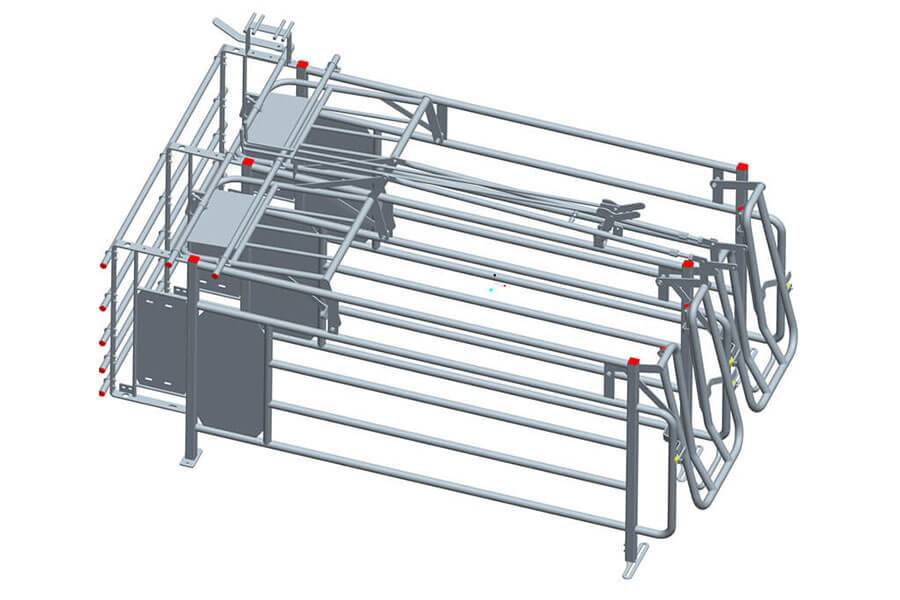

Structure: Pig farrowing crate is also called pig farrowing house or pig farrowing fence. A pig farrowing crate includes sow locating frame, piglet fence, piglet incubator, manure dropping floor, trough for sow and supplementary feeding trough for piglet, etc. The locating frame is used for control the free range of sow’s movement. There’re bars between each locating frame, in order to avoid being run over of the piglet.

Material & Crafts: The sow locating frame is generally 2.1-2.4 meters long, 1.0 meters wide. After welded, the whole set will adopt hot galvanizing technology, including the welded junction. So the welded junctions are fastness with no burr. It can avoid rusting and breaking, and totally no harm to the pigs. At the bottom of the locating frame, there are curving bumping columns which can protect the piglets .

Piglets fence provide activity space and prevent them from running off. The fence adopted clapboard design, which can prevent diseases efficiently. There is space between farrowing crate and sow tail, making the workers help sow to farrow more convenient, also good for piglets moving freely. The supplementary feeding trough and the waterer bowl are at the back of the fence. It also has defecation area at the back. The floor of the arrowing house are made of plastic and cast iron.

Features of Pig Farrowing Crate

- Clean delivery environment, which can help sows get better recovery and release their highest potential abilities of parturition.

- Convenient for workers to take care of the sow and piglets.

- It can protect piglets, avoid being trodden by sow.

- It can supply better sanitary condition, which can keep bacteria off. Reduce the morbidity of piglets.

-

Supporting Facility of Pig Farrowing House

- The support beam of farrowing house and floor for sow adopts nodular cast iron. The floor for piglets adopts plastic leaky board, extremely satisfying the need of sow and piglets.

- The support of the farrowing crate frame adopts hot galvanizing technology, which are sturdy and durable, anti-fading & anti-corrosion.

- The whole set are assembled by bolts, which are easy and convenient to dismantle. We also have incubator, heating lamp, water trough for sow & piglets, feeding trough for piglet for customer to choose.

-

Highlights of Farrowing House Supporting Facility

- The whole support beam of farrowing house are made of nodular cast iron, which are durable and anti-corrosion.

- Our nodular cast iron adopts epoxy aluminum coating resin sand technology, so the products have no burrs and will not hurt the pigs

- After improving the technology level, we diminishes the gap of the floor (for sow use) to 8.5-9mm. The traditional standard is 11-12mm. At present we are the only manufacturer which can achieve this level. It can totally avoid the damage to the sow’s nipples which caused by the gap of the floor

Slatted Plastic Floor

Floor for sow adopts nodular cast iron; floor for piglets adopts plastic leaky board.

All of our plastic floors are made of PP materials, and single reinforcement can bear 150kg. It is totally meet the international standard and the chance of broken by the piglet is zero.

We Supply 3 Models of Pig Farrowing Crates & Conjoined Pig Farrowing Crate

Farrowing house is a necessities of modern pig farming. It is a determining factor of whether a pig farm is successful or not. The key elements of design a farrowing house are breed of the sow and the level of the environment in the whole workshop. The breed decide the bodily form of the sow, and the level of the environment decide the space design for the piglet. We broke the traditional design philosophy, and design the most suitable farrowing house according to customer’s requirement. The key factor of achieve production index is also suitable equipments.

The Technical Data of Pig Farrowing Crate

| Model | CC-A1 | CC-B1 | CC-C1 |

|---|---|---|---|

| Overall Size | 2.4*1.8m/unit (one sow position) | 2.2*1.8m/unit | 2.2*1.8m/unit |

| Manufacturing technique | Overall hot galvanizing technology | Overall hot galvanizing technology | Overall hot galvanizing technology |

| Tube size | GB One inch tube | GB One inch tube | GB One inch tube |

| sow location | Nodular cast iron floor | Nodular cast iron floor | Nodular cast iron floor |

| Piglet location | Plastic slatted floor | Plastic slatted floor | Plastic slatted floor |

| fence material | PVC | PVC | PVC |

| Three models differences | CC-A1 can adjust according to the sow’s size. The range is 8cm from left to right, 3-4cm from back to forth. |

CC-B1 can adjust width from left to right. |

CC-C1 is of fixed dimension. |

For any enquiries, please fill in contact form.

Thank you for your cooperation.